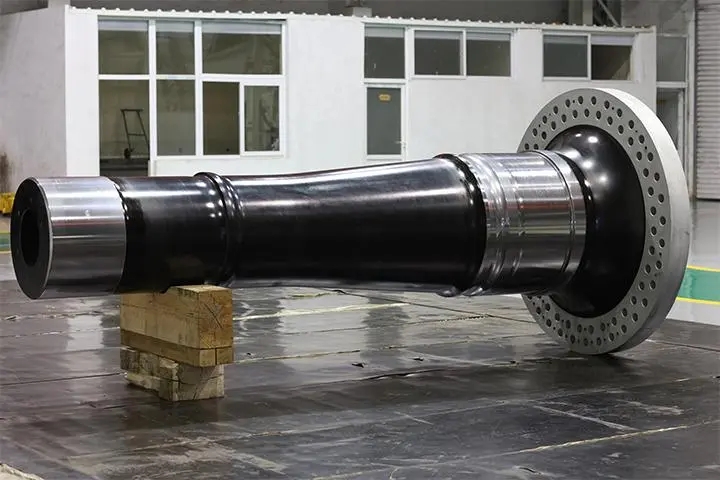

Nuclear Power Spindle

Brand Jiayang

Product origin China

Delivery time scheduled delivery

Supply capacity good

1. High speed: the wind power spindle needs to have a high speed, generally between 1000-2000 RPM, to meet the working requirements of the wind turbine.

2. High precision: the wind power spindle needs to have a high precision to ensure the smooth and reliable operation of the wind turbine. Its accuracy requirements are mainly reflected in the selection of bearings and processing technology.

3. Height: the wind power spindle needs to have a high stiffness to withstand the bending and extrusion pressure of the wind turbine under the action of the wind. Its stiffness is mainly reflected in the structural design and material selection of the spindle.

4. Lightweight: the wind power spindle needs to have a light weight to reduce the overall weight of the wind turbine and improve the convenience of its transportation and installation.

5. High wear resistance: Wind power spindle needs to have high wear resistance to extend its service life. Its wear resistance requirements are mainly reflected in the design and selection of bearings and lubrication systems.

6. High reliability: the wind power spindle needs to have a high reliability to ensure the long-term stable operation of the wind turbine. Its reliability requirements are mainly reflected in the design and manufacturing process of bearings and transmission systems.

Wind power spindle refers to the main bearing component in the wind turbine set, which is used to support and rotate the rotor of the wind turbine. The wind power spindle is made of high-strength alloy steel material, with high strength and stiffness, and can withstand huge torque and rotation speed.

1.Wind power is usually supported by two main bearings, a ground bearing located at the bottom of the fan tower, used to support the weight of the entire wind turbine; A top bearing located at the top of the fan tower that supports the weight of the rotor and allows it to rotate freely.

2.The design and manufacture of wind power spindle need to consider many factors, including rotor quality, speed, torque, vibration and so on. The selection and lubrication method of the main bearing also need to be selected according to the specific working conditions and environment to ensure that the spindle can run stably and has a long service life.

3.The reliability and performance of wind power spindle have an important impact on the operating stability and power generation efficiency of wind turbines, so in the wind power industry, the development and improvement of wind power spindle has been an important topic.